- Food-compatible according to FDA

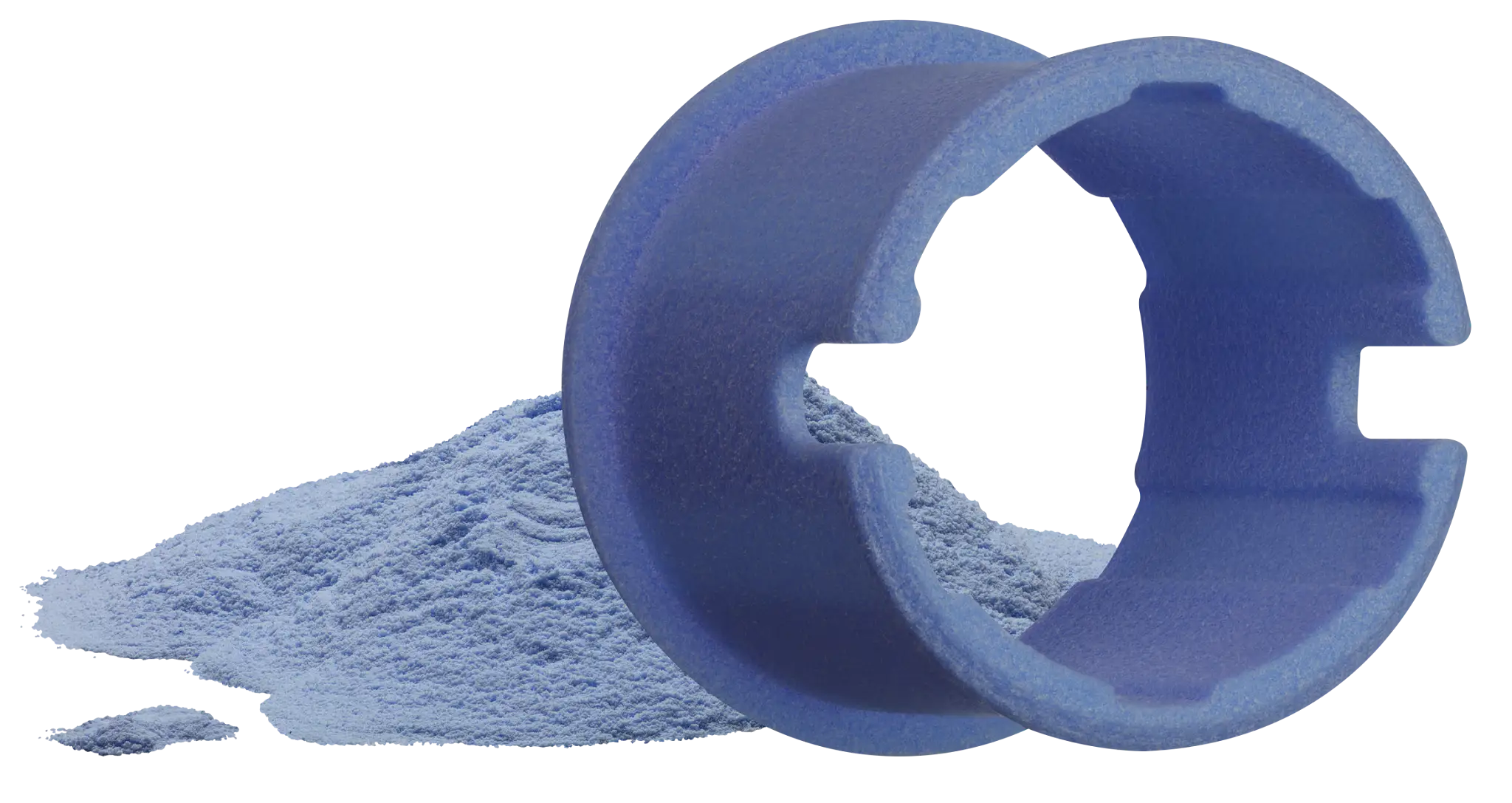

- Blue colour for optical detectability

- High abrasion resistance

- Robust

- Accurate surface details

- Ideal for worm wheels

iglidur® i6-BLUE, laser sintering material

The food conformity declaration and data sheets for iglidur i6-PL can be found in the "Downloads" tab.

Selective laser sintering (SLS) material: iglidur® i6-BLUE

The material iglidur i6-BLUE

material was designed specifically for laser sintering and developed in particular for manufacturing worm wheels and for contact with food. Tests in the igus test laboratory showed that this material had a longer service life than gears conventionally milled from materials such as POM. This greatly increases design flexibility for sliding components subject to wear as laser sintering requires no tools, so that special parts can be manufactured efficiently with no minimum order quantity. Furthermore, iglidur® i6-BLUE is ideal for snap-on connections due to the higher elongation at break.

When to use it?

- When a food-compliant material in solid blue is required (optical detectability)

- For applications with sliding motion, especially for worm gears

When not to use it?

- For applications under water or with high humidity (→ iglidur i8-ESD)

- If components with ESD specifications are needed (→ iglidur i8-ESD or iglidur i9-ESD)

- In combination with anodised aluminium as a mating partner (→ iglidur i3)

- For gear applications (→ iglidur i3)

- If the application temperature is higher than 80°C in the long term (→ iglidur A350 or iglidur RW370)