Change Language :

Chemical-resistant energy supply systems for electroplating

Electroplating systems place extremely high demands on the components installed. In the electroplating process, strong chemicals are used in the electrochemical bath, which the energy supply systems and the cables fitted in them must withstand. Where steel energy chains reach their limits, plastic energy chains come into their own. Energy chains are chemical-resistant and corrosion-free, lightweight, cost-effective and, thanks to their optimised sliding properties, ensure a long service life and maintenance-free operation. The cables in the energy chain must also withstand the demanding environment. We can show you solutions specifically designed for electroplating systems.

55 years of experience in plastics for motion

We know what applications need and what customers want. We know our products and their properties inside out.

And we show you how you can benefit from them and get your Tech up and Cost down.

Tech up

Improved ease of assembly

... with a new locking principle

The easy-to-handle and easy-to-fit trough can be installed in no time at all. This means less assembly work for the installer. In a test installation by igus installers, a 30-metre-long trough was fitted in less than 3 minutes thanks to the practical assembly method.

The side parts are connected by clipping and snapping into place by hand without tools. The clamping mechanism, specially designed for the system, then holds them securely and resiliently together. The quick assembly significantly reduces working time and costs.

Lightweight facilitates use and reduces costs

... with the guidelite plus made from igumid EG+

On the subject of weight: 1 metre of guidelite plus EG weighs only 1.8kg, while 1 metre of stainless steel guide trough weighs 7.5kg. The use of plastic makes heavy metal guide troughs obsolete. Metal guide troughs are susceptible to corrosion and are costly, both in terms of acquisition as well as installation and maintenance.

Tribopolymers have been used to design a much lighter guide trough for harsh environments, which is characterised by smooth running and corrosion resistance. The potential weight savings pay off immediately in design, operation and purchasing.

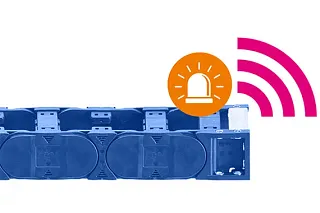

100% safety plus maintenance indicator

... with smart plastics

These components give you system and planning reliability. If a component on the energy supply system wears out or is damaged, the sensors detect this and either emit a signal or shut down the system as a precautionary measure to prevent expensive consequential damage. Furthermore, the sensors provide a predicted maintenance recommendation for individual components (chain or cable) so that you always know if and when maintenance is required. This saves time and money.

Cost down

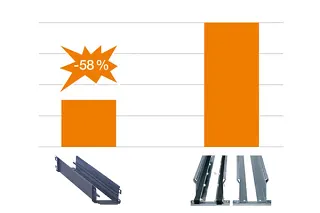

Save up to 58% on purchasing costs

... compared to stainless steel guide troughs

Metal guide systems have the familiar problems: Corrosion, complex installation, high weight and high costs. The material used for the guidelite plus EG guide trough ensures high chemical resistance, making it ideal for use in electroplating and fertiliser production. Due to its light weight and modular design, the installation process is significantly simplified.

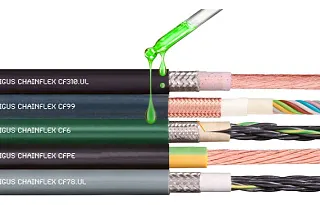

Save up to 35% on purchasing costs

... with robust chainflex cables

In various areas and applications, the use of single-core cables for motors has led to significant cost savings in purchasing, as these are up to 35% cheaper to procure as a complete cable package including PE protective conductor than, for example, a solid 4-core CF35.UL motor cable.

In addition, an increase in the service life of cables has been observed, as single cores can be used in a smaller installation space, which also benefits the mechanical layout of the entire energy chain system.

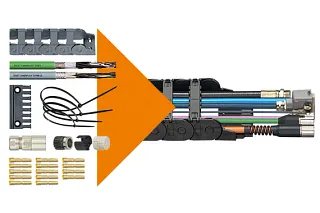

95% less assembly time

... with ready-to-install energy supply systems

Energy supply systems installed in electroplating systems must be able to withstand the demanding environment. It is important to select the right materials for the individual components and to ensure that they are compatible with each other.

This is where pre-fitted readychain energy supply systems come into their own. They are specially designed for the relevant environmental conditions and can be installed on site in a few simple steps. This significantly reduces assembly costs and installation time.

Proof

Energy chain systems proven in hundreds of thousands of applications worldwide ►Find out more

Sustainability

Yes, plastic energy chains are recyclable

Have your drag chains or energy chains,

regardless of the manufacturer, processed in the igus Chainge recycling programme

so that recyclable granulate can be obtained.

We will be happy to assist you

Learn more about the advantages of energy supply systems for electroplating. Together, we will find the solution that will get your Tech up and Cost down. If you have any questions, I will be happy to advise you.

I look forward to hearing from you!

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr