Change Language :

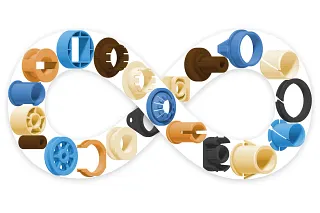

iform – Toolmaking by igus

Precise moulds are a prerequisite for high-quality components. At igus, we manufacture the moulds for our injection moulding in iform, our in-house tool shop. In addition to complete moulds specially tailored to individual product requirements, we also manufacture moulds in a modular system consisting of tool extensions and mould inserts. We can quickly fit various mould inserts into an assembly that is built onto the injection moulding machine and thus manufacture a wide variety of products.

From mould development through production and sampling to quality control with computer tomography support, the creation of a mould is therefore completely in our hands. This gives us the opportunity to implement requests for individual components at short notice and in perfect quality. As mould making is involved in development and consultation with the customer at an early stage, we can offer not only suitable materials but also the right tool manufacturing processes to reduce overall costs. Depending on the order volume, a mould can also be produced as print2mold in 3D printing, also on site naturally and made from our proven high-performance plastics.

Main tasks of our iform tool shop

- Development, production and sampling of tool technology for all igus injection-moulded products

- Enabling the fastest possible mould repairs and maintenance to ensure delivery capability for our customers

- Designing technically new products together with sales, development and production

100

employees

1,550m²

floor area

32

processing machines

Over 3,000

tool assemblies

Over 1,000

mould inserts per year

Fast production with FastLine: injection-moulded special plain bearings in seven days

RWTH Aachen University and Fraunhofer Institute select iform as the Toolmaker of 2022

Experience the igus factory in 360° now

What actually happens in our factory at our headquarters in Cologne? Immerse yourself in our 360° VR world and discover the various stations from injection moulding and the tool shop to quality control and our laboratory. All stations are accompanied by interesting information about the factory and the machines.

Step by step to the finished tool

Tool production

Our pool of 32 machines are equipped with state-of-the-art processing machines and a wide range of manufacturing technologies. By networking the machines and using automation, we are able to manufacture the most demanding components in the shortest possible time while maintaining the tightest tolerances.

High-volume production of individual injection-moulded parts

From the drawing with the right manufacturing process up to high volume production of your customised components made of technical plastics from igus.

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr