Change Language :

Instructions for replacing DIN 103

Change in DGE: From thread geometry TR to DS

Replacing the trapezoidal thread geometry selected by the thread drive experts with the dryspin® thread geometry is not always intuitive. To ensure that nothing goes wrong during the replacement process, we have summarised the individual steps in detail and with illustrations. If you are still unsure, please contact one of our experts. We will go through the individual steps with you and find a suitable solution for you.

You can find out in advance about the advantages of replacing conventional trapezoidal DIN 103 threaded spindles. Visit: dryspin® Alternative to DIN 103 trapezoidal threads.

Step 1: Go to the configuration step "1 Select version"

Step 2: Scroll down to select "Thread size"

Step 3: Click on TR dimension and open drop-down menu

Step 4: Scroll to the alternative DS dimension and click on it

Step 5: Confirm using the button "Continue" - Done!

Explanation of the dryspin® technology

High efficiency and low wear

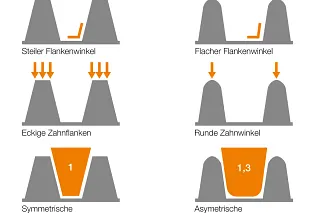

The patented dryspin® steep thread technology was developed by igus® in 2013 and offers numerous advantages over conventional steep threads. Due to the flat flank angle, it efficiently converts the applied force into a translational movement. With the specifications and geometries matched to the plastic nut and spindle, dryspin® offers even greater service life and efficiency for steep threads. Thanks to the rounded tooth flank geometry, the contact surface between the threaded spindle and lead screw nut is reduced and the threaded systems run almost silently and vibration-free under load.

The larger distances between the individual dryspin® threads increase the proportion (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and a higher degree of efficiency are decisive for a service life that is up to 5 times longer than that of conventional steep threads.

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr