Change Language :

Maintenance-free heavy-duty and fibre composite plain bearings

What you will find on this page

Benefit from igutex composite bearings and iglidur plain bearings

Our high-strength igutex fibre composite plain bearings

What is special about igutex fibre composite plain bearings?

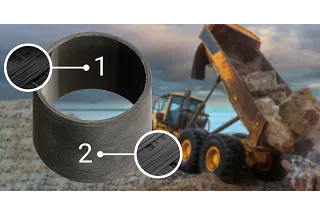

Where injection-moulded plain bearings cannot be used due to excessive mechanical loads, wound igutex fibre composite plain bearings come into their own. They consist of two layers:

1 gliding layer

The gliding layer consists of a filament fabric with solid lubricants, which makes the composite plain bearings self-lubricating and maintenance-free and gives them a particularly low coefficient of friction.

2 Base layer

The outer layer of igutex plain bushings is made from very hard-wearing filament fabrics and serves to protect the tribologically optimised inner layer.

igutex fibre composite plain bearings are used here

Our iglidur heavy-duty plain bearing

What is special about iglidur plain bearings?

iglidur plain bearings are developed from very wear-resistant plastic with a very low coefficient of friction. Over 60 different iglidur materials are available and are each developed for special applications. All contain solid lubricants and are therefore suitable for use without additional lubrication and maintenance.

In addition to polymers, iglidur plain bearings for heavy-duty applications contain fibres and fillers, which give them their high wear resistance. This means they can be used without problems with high forces and edge loads.

Thanks to a large database with test results, the service life can also be determined for various operating conditions.

Here iglidur heavy-duty plain bearings are in use

Free consultation without obligation

Our experienced application specialists analyse your bearing points and work with you to develop the optimum lubrication-free system.

• Request support online

• Arrange an appointment on request

• Support available over phone or video chat

Request advice now

Free sample box with igutex plain bearings

Request our free sample box of heavy-duty plain bearings now. Included are:

✅ igutex plain bearings

✅ iglidur plain bearings

✅ Plain bearings with felt seal

✅ Test results

✅ Application examples

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr