Change Language :

drylin - best coefficient of friction, lowest wear

Materials

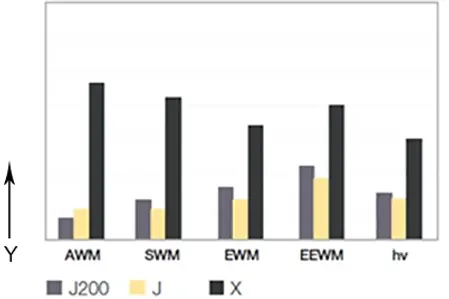

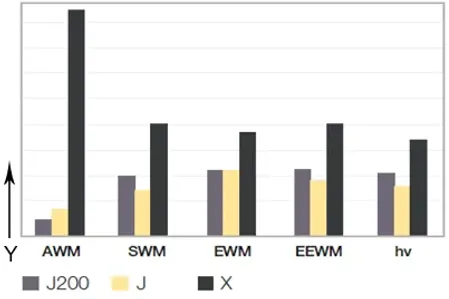

igus offers various materials for sliding elements and mating partners for drylin linear systems. Years of testing have shown that iglidur J, J 200 and X are the ideal materials for most linear applications due to their wear and friction properties.

Optimum combination of materials

iglidur J

The material iglidur J achieved the best results in our tests on almost all shaft materials. Comparative laboratory tests show that iglidur J is the polymer with the lowest friction and wear for linear applications.

Special specifications of

iglidur J:

- Maintenance-free dry operation

- Low coefficient of friction with all materials

- Excellent wear resistance

- Very low moisture absorption

iglidur J200

iglidur J200 was specially developed for linear applications in combination with hard-anodised aluminium surfaces. This combination achieved by far the best results in our laboratory tests.

Special specifications of iglidur J200:

- Absolutely maintenance-free

- Extreme service life on hard anodised aluminium

- Low coefficient of friction with anodised aluminium

- Excellent wear resistance with anodised aluminium

iglidur X

iglidur X is characterised by its high temperature resistance and compressive strength, combined with extreme chemical resistance. iglidur X achieves its best wear resistance on stainless steel and chrome-plated steel shafts.

Special specifications of

iglidur X:

- Absolutely maintenance-free

- Temperature resistance -100°C to +250°C in continuous operation

- Universal chemical resistance

- Very low moisture absorption

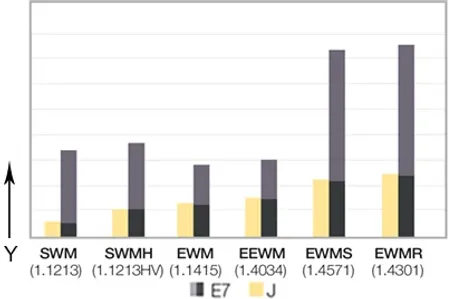

iglidur E7

iglidur E7 is the specialist for steel and stainless steel shafts. This material is very vibration-dampening and particularly abrasion-resistant and achieves an eight-fold higher service life.

Special specifications of iglidur E7:

- Quiet operation due to good dampening properties

- Extremely low coefficient of friction

- Self-lubricating due to incorporated solid lubricants

- Corrosion-free

- Very low moisture absorption

Y = coefficient of friction

Y = coefficient of friction

Y = Wear

Y = Wear

Y = service life

Y = service life

| AWM(P): | Hard-anodised aluminium shaft h10 or h8 |

| SWM: | Hardened and ground steel shaft, h6, (AISI 1055) |

| EWM: | Hardened and ground stainless steel shaft, h6, (AISI 440C) |

| EEWM: | Hardened and ground stainless steel shaft, h6, (AISI 420C) |

| hv: | Hard chrome-plated and ground steel shaft, h7, (AISI 1055) |

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr