Five reasons why you should use iglidur plain bearings in motor vehicles

Free sample box

Convince yourself of the quality of our iglidur plain bearings and request the free plain bearing sample box now. Included in the box are:- Plastic bearings made of different iglidur materials and with different assembly concepts

- Bar stock made of iglidur material

- Individually manufactured coupling joint

- Energy chain with cable

Order now!

Reason 1: Reduce costs by up to 40%

Ongoing pricing pressure is forcing OEMs and parts suppliers to optimise their costs continually. Low-cost tribo-polymers are a commonly used alternative to expensive metal bearings.

Today, almost every motor vehicle that is made contains polymer bearings as a substitute for metal plain bearings and rolling bearings. The range of applications extends from seating systems to thermally demanding applications in the engine compartment, for example in gearshift forks for gearboxes, in coolant pumps or in the powertrain.

Why are plastic bearings more cost-effective than metal rolled bearings?

Today, almost every motor vehicle that is made contains polymer bearings as a substitute for metal plain bearings and rolling bearings. The range of applications extends from seating systems to thermally demanding applications in the engine compartment, for example in gearshift forks for gearboxes, in coolant pumps or in the powertrain.

Why are plastic bearings more cost-effective than metal rolled bearings?

- Less energy required in the manufacturing process

- 11,000 litres of crude oil are needed to make 1m³ of steel; for 1m³ of plastic, only 1,000 litres of crude oil are needed

- Short cycle times in the manufacturing process

- Greater amount produced per cycle due to multiple activities in the injection-moulding procedure

- Due to precise manufacturing, downstream manufacturing stages are usually unnecessary.

2nd reason: save up to 80% weight

Legal requirements require a continuous reduction in vehicle emissions. This is achieved, among other things, by reducing the weight of the vehicles. This results in another advantage: less weight leads to lower fuel consumption.

A modern iglidur plastic plain bearing is up to 80% lighter than a conventional metallic plain bearing of the same dimensions. The number of bearing points has grown continually alongside the increase in vehicle complexity. This means that weight is an important factor to be considered when the bearing material is selected.This is where iglidur polymer plain bearings display their advantage: they weigh less than metal bearings and therefore contribute towards the reduction of carbon-dioxide emissions. In addition, significantly less crude oil and therefore less energy is required to produce them, and they also work completely lubrication-free.

For alternative drive concepts as well, the advantages of iglidur plain bearings are decisive. Lightweight and exceptionally quiet components are required here that do not produce any annoying noises during operation and thus increase driving comfort.

A modern iglidur plastic plain bearing is up to 80% lighter than a conventional metallic plain bearing of the same dimensions. The number of bearing points has grown continually alongside the increase in vehicle complexity. This means that weight is an important factor to be considered when the bearing material is selected.This is where iglidur polymer plain bearings display their advantage: they weigh less than metal bearings and therefore contribute towards the reduction of carbon-dioxide emissions. In addition, significantly less crude oil and therefore less energy is required to produce them, and they also work completely lubrication-free.

For alternative drive concepts as well, the advantages of iglidur plain bearings are decisive. Lightweight and exceptionally quiet components are required here that do not produce any annoying noises during operation and thus increase driving comfort.

3rd reason: reduce noise (BSR -buzz, squeak and rattle)

One technical challenge for vehicle and component engineers is to identify the 'noisy' components and replace them with a quieter solution wherever possible. The expectations of the OEMs in this context are increasing continually. The reason is that alternative drive systems such as hybrid or electric motors work a lot more quietly, making the interior of the vehicle quieter and making BSR noises - otherwise masked by the loud combustion engine - much more perceptible.

How do iglidur plain bearings reduce noise?

With our tribologically optimised high-performance polymers, you achieve an especially low coefficient of friction and therefore a quiet application. Whether in seats, hinges or actuators, the variety of applications for our iglidur plain bearings inside vehicles is great.

How do iglidur plain bearings reduce noise?

With our tribologically optimised high-performance polymers, you achieve an especially low coefficient of friction and therefore a quiet application. Whether in seats, hinges or actuators, the variety of applications for our iglidur plain bearings inside vehicles is great.

Plastic is characterised by the fact that, unlike metal, it has a damping effect. In applications involving severe vibrational stress, plastic bearings help reduce noise. Our iglidur product range includes materials that have especially good damping properties.

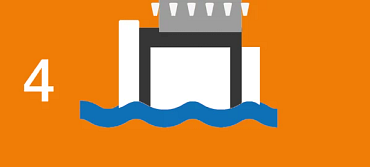

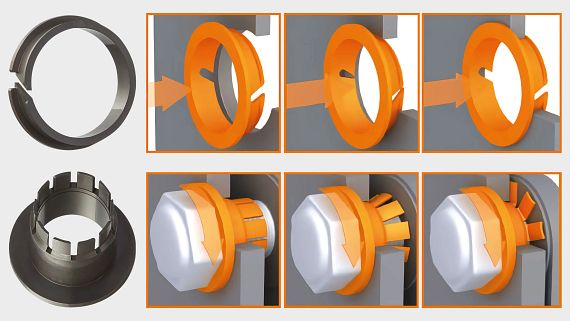

4th reason: self-calibration

Whether in convertible tops, steps, spoiler kinematics or vehicle seats: hinges are often equipped with metallic rolled bearings with a PTFE coating. However, since there are usually rough housings and collared grooves at these points, these bearings have to be laboriously recalibrated in order to achieve a low-clearance system. iglidur plain bearings calibrate themselves due to the effect of heat in the e-coating process and ensure that they fit in place exactly.

... and this is how it works

Step 1

Given is a roughly punched housing or a roughly punched collared groove with nominal dimension range H10 or H11.

Step 2

The iglidur plain bearing is inserted into the hole or collared groove with a sliding fit.

Step 3

Pin or rivet with cap is force fitted in the bearing point.

Step 4

The e-coating (cathodic dip painting) is carried out with the installed iglidur plain bearing and the pin or rivet.

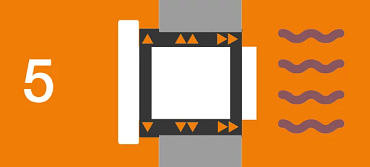

Step 5

The bearing point is dried. Due to the effect of heat, the iglidur plain bearings calibrates itself in the bearing point. Suitable for up to 220°C and a maximum drying duration of 60 minutes.

Step 6

The result: a low-clearance bearing support in spite of holes and pins with large tolerance.5th reason: flexible installation concepts

Thanks to our modern injection-moulding method, the desired iglidur plain bearing can be made in almost any geometry. As a flexible clip bearing, flange bushing or double flange bushing specifically for a quick installation in sheet metal. Customised special solutions made of plastic in the desired shape, quantity and material are also possible.

Moreover, we can provide you with your desired special geometry within 48 hours as a sample for your tests.

Moreover, we can provide you with your desired special geometry within 48 hours as a sample for your tests.

Discover our sheet metal solutions now

Free sample box

Convince yourself of the quality of our iglidur plain bearings and request the free plain bearing sample box now. Included in the box are:- Plastic bearings made of different iglidur materials and with different assembly concepts

- Bar stock made of iglidur material

- Individually manufactured coupling joint

- Energy chain with cable

Order now!

More information

Application locations

Inside and out: our motion plastic products show their advantages in numerous places in the carGet an overview

Go back to overview

To the introductory page with further areas of application for our products and information on special servicesGo to overview