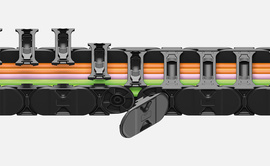

Heavy duty rol e-chain® P4HD.56R

For maximum service life with optimised design

The new heavy-duty rol e-chain meets all the relevant requirements for container cranes of the next and next-but-one generations.Longer and longer travels, greater dynamics, short stress cycles, zero failures: in brief, this is what is demanded by the manufacturers of ship-to-shore container cranes for energy chains on the crane bridges. The new P4HD.56R fulfils these requirements - and offers maximum economic efficiency.

Ask for a free sample now

Longer service life: maintenance-free tribo-polymer plain bearings

Secure guidance: comb-like autoglide crossbars

Prediction maintenance with i.Sense: optional

Tech up

- Developed for the coming generations of STS cranes

- Service life extended again (compared to P41.56R) + 50%

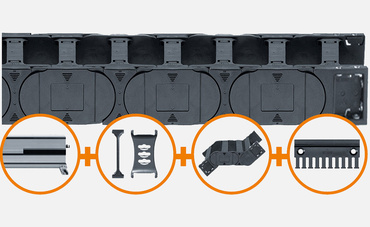

- Everything redesigned: rolling elements, side bands, joining links

- Integration of predictive maintenance sensors possible (i.Sense)

Cost down

- Low maintenance

- Minimised downtime when using i.Cee module (failure always means high costs)

- Retrofitting easy - guide troughs remain identical

- Predictive maintenance - ideal with the i.Sense add-on module

Proof

- In-house testing facility: for tests at up to 8m/s over a travel of 400 metres

- 50% longer expected service life compared to the proven P4.1 series

Sustainability

- 57% drive power, saving energy

- Have your energy or drag chain recycled at the end of its life cycle in the igus Chainge® recycling program. No matter what manufacturer.

- igus supports the plastics circular economy and is investing in chemical recycling. From plastic waste to crude oil in 20 minutes.

"Chains for cranes®" next level:

we want a service life of 15 years for e-chain systems - on every crane. This is our development goal and can also be found in the functional specifications for the new P4HD product range. New standards in container shipping are demanding more and more of energy chains used on STS cranes. igus, the energy supply specialist, presents a new generation of extremely long-lasting rol e-chains specially developed to meet these new challenges – the P4HD.56R.

we want a service life of 15 years for e-chain systems - on every crane. This is our development goal and can also be found in the functional specifications for the new P4HD product range. New standards in container shipping are demanding more and more of energy chains used on STS cranes. igus, the energy supply specialist, presents a new generation of extremely long-lasting rol e-chains specially developed to meet these new challenges – the P4HD.56R.

Product range:

| Part No. | Inner height | Outer height | Inner width | Outer width | Bend radius | |

|---|---|---|---|---|---|---|

| P4HD.56R | 56 mm | 84 mm | 187 - 300 mm | 269,5 - 382,5 | 250/300/350mm |  Submit an enquiry now Submit an enquiry now |

Available from stock

Additional feature: predictive maintenance with smart plastics

In the latest development stage of the igus rol e-chains, use of maintenance-free, tribo-polymer plain bearings in the connection of the e-chain links also considerably lengthens the service life. Optionally, the new P4HD can be equipped with smart monitoring sensors. A signal is issued from a defined wear limit to the igus i.Cee:plus communication module, with which maintenance can be planned in advance. The sensor is integrated into a standard side part of the chain, which does not lead to any restrictions in the usable inner width.Find out more

Free white paper:

Triple E-class container ships and the requirements of energy supply for STS cranes

This white paper deals with the following topics, amongst others:

- The challenge: cranes for Triple E-class container ships

- Crane availability and dependability requirements

- A comparison of energy and signal supply lines to the crane trolley (festooning, busbar systems and energy chains)

- Technological outlook: rol e-chains

Download white paper now

The revolution of the rol e-chain

The roller energy chain has been the tried-and-tested energy supply for long travels for about 20 years. The successful design that characterises all our linear energy chain systems is supplemented by rollers made of stainless steel, which upgrade the energy chain to an energy supply for heavy-duty applications. As the energy chain rolls and does not glide, it runs silently and with low vibration. The wear is significantly lower than with a design without rollers, and the power needed for the movement is also about 57% lower.Find out more

More information

rol e-chain® P4.1

The P4.1 rol e-chain series make it possible to increase plant safety and availability.To the P4.1

Energy chain complete set

For long travels. Time-saving and cost-effective with complete energy chain sets.To the complete set

readychain harnessing

With our ready-to-connect energy supply systems, it is possible to reduce the harnessing time by up to 95%.To readychain

Further products for crane systems

Our energy chain systems have proven their reliability all over the world in ship-to-shore cranes, bulk cargo handling cranes, RTGs, RMGs, Goliath cranes, spreaders and reach stackers . They require very little maintenance, are robust, durable and quiet in use, while also being an alternative to busbars, festooning and motorised cable reels.Discover further products now

You might also be interested in

Energy chain standard product range

Shop with more than 100,000 products.To the standard product range

Energy chain configurator

Assemble your individual energy chain system in just a few steps.Go to the configurator

Savings potential

Discover your potential savings with energy chains now.To the savings potential

Recycling programme

Have energy chains recycled instead of throwing them away.Go to recycling programme