Predictive maintenance with i.Cee:plus II: a whole lot of Industry 4.0 in one device

New i.Cee:plus module enables deep integration into customer networks and numerous IoT use cases

i.Cee = "I see ahead" - now also in our customers' network environments and IoT concepts. The 2nd generation of the i.Cee:plus module creates the optimal framework conditions for predictive maintenance entirely in the interest of the customer. This is because the possibility of seamless integration into the designated network environments of the respective applications enables the creation of the most diverse Industry 4.0 use cases.From preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels, up to comprehensive sensor data management, which even enables the integration of 3rd party cloud solutions, everything is feasible. All information is aggregated in a modern dashboard, online or offline in the local network depending on the customer's requirements.

This makes the 2nd generation i.Cee:plus module the heart of every Industry 4.0 energy supply system, always with the aim of achieving maximum equipment and user safety as well as product service life.

Part number: IS.PLUS.01.01.0.BETA

Make an appointment directly for a live demo

Tech up

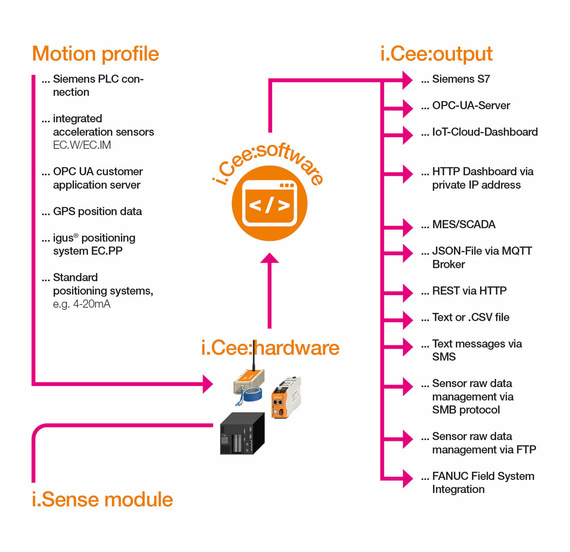

- Numerous, modern connections for optimal sensor data management (IoT integration, 3rd party cloud solutions, etc.)

- Increased connectivity for absolute transparency –

"anytime, anywhere, anyhow" (network connections: dashboard on local intranet, connection to PLC and plant monitor, communication with local 3rd party software via JSON/MQTT/REST/. CSV/. TXT, optional connection to cloud solutions)

Cost down

- Maximise product service life through efficient retrofit management

- Avoid unplanned plant downtime and downtime costs with predictive service management

Proof

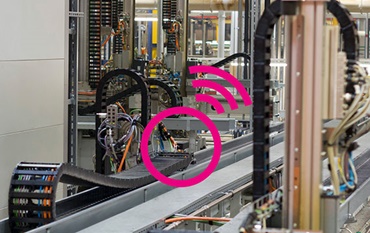

- Ongoing testing in the industry's largest test laboratory for dynamic

energy transmission systems - In operation in Poland since January 2021 on a 440m

travel path

Sustainability

- Savings in physical travel costs through remote linkages

- Unplanned service deployments can be prevented - eliminating 100km of travel saves about 3.6kg of CO²

What does igus predictive maintenance (i.Cee) mean?

Smart networking of individual components creates the solid foundation for predictive maintenance concepts. At igus®, we call our predictive maintenance system "i.Cee.The central element of this system is the i.Cee software. Sensors on the energy chain, the plain bearing bush, or a linear carriage, transform products deliverable from stock into smart products. This upgrade creates the capability of determining your igus® product's maximum service life, and the i.Cee system also tells you the perfect time for servicing it. Algorithms adapt the service life and the service time to the equipment's use. The software we provide and a few sensors transform standard products available from stock into smart energy supply or bearing technology in no time.

Learn all about predictive maintenance here

You determine the manner of data transfer and access

Data transfer within your local corporate network (i.Cee:local) or on a secure cloud (i.Cee:cloud)

i.Cee:local

The options range from an energy chain within a single machine to a machine park and your own output interface.

i.Cee:cloud

The igus® white paper on predictive maintenance

Clarifies the distinction between condition monitoring and predictive maintenance

In this white paper, you will find out:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems

- What the two systems offer industrial energy supply

Go to free download

Industry 4.0: real-world examples

Customer applications with smart plastics

Aluminium oxide production

"If movement of the chain is excessively hindered by dust or dirt, the push/pull monitoring shuts down the system before any damage can occur."

Aluminium Oxid Stade GmbH (AOS)

Aluminium Oxid Stade GmbH (AOS)

To the application report

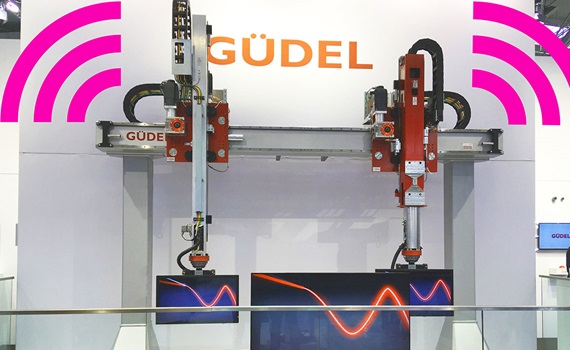

Linear robots

Due to the integration of smart plastics sensors into the energy supply, the customer's condition monitoring system is supplied with data.

Güdel Deutschland GmbH

Güdel Deutschland GmbH

To the application report

More smart applications

Find further successful application examples of our smart plastics customers.

smart plastics application examples

Smart consulting tool

Find out more

Smart brochure

Find out more